Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:214 Source:ROLL FORMING MACHINES LTD

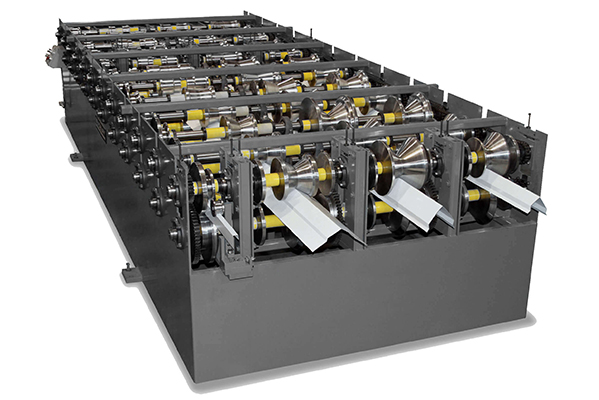

Roll forming machines have become indispensable in the manufacturing industry, offering a versatile and efficient means of producing a wide range of products. This article provides a detailed analysis of roll forming machine processes, focusing on their applications across various industries. By understanding the specific requirements and challenges of each application, manufacturers can tailor the roll forming process to optimize product quality and production efficiency.

Automotive Industry

In the automotive industry, roll forming machines are extensively used to produce components such as frame rails, door beams, and roof rails. These components require high strength and precision to ensure the safety and structural integrity of the vehicle. The roll forming process allows for the continuous bending of sheet metal into complex shapes, ensuring consistent wall thickness and dimensional accuracy. Additionally, the ability to produce long, seamless parts reduces the need for welding, which can weaken the material and increase production time.

Aerospace Industry

The aerospace industry demands precision and reliability in its components, making roll forming an ideal manufacturing process. Roll forming machines are used to produce parts such as aircraft fuselage sections, wing spars, and landing gear components. The process enables the production of lightweight, strong, and corrosion-resistant parts from materials like aluminum and titanium. The continuous bending process ensures that these parts maintain their shape and structural integrity, even under extreme conditions.

Building and Construction

In the building and construction industry, roll forming machines are used to produce a variety of structural components, including roofing, wall panels, and framing members. The roll forming process allows for the efficient production of these components in long, continuous lengths, reducing waste and increasing production speed. Additionally, the ability to produce parts with consistent dimensions and wall thickness ensures structural integrity and durability, making them ideal for use in both residential and commercial buildings.

Furniture Manufacturing

Roll forming machines are also used in furniture manufacturing, particularly for producing metal frames and components. The process enables the production of intricate shapes and designs, while maintaining precision and consistency. This is particularly important in the production of high-end furniture, where attention to detail and quality are paramount. Roll forming also allows for the efficient production of large quantities of parts, reducing labor costs and increasing production capacity.

Appliance Manufacturing

In the appliance manufacturing industry, roll forming machines are used to produce components such as refrigerator frames, washing machine cabinets, and dryer drums. The process allows for the efficient production of these parts in a variety of materials, including stainless steel and galvanized steel. The continuous bending process ensures that these parts maintain their shape and durability, even under the stress of daily use. Additionally, the ability to produce parts with consistent dimensions and wall thickness ensures a tight fit and finish, enhancing the overall quality of the appliance.

Conclusion

Roll forming machines offer a versatile and efficient means of producing a wide range of products across various industries. By understanding the specific requirements and challenges of each application, manufacturers can tailor the roll forming process to optimize product quality and production efficiency. Whether it's producing structural components for the aerospace industry, furniture frames for high-end design, or appliance components for daily use, roll forming machines provide a reliable and cost-effective solution for manufacturing a diverse range of products.