Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:247 Source:ROLL FORMING MACHINES LTD

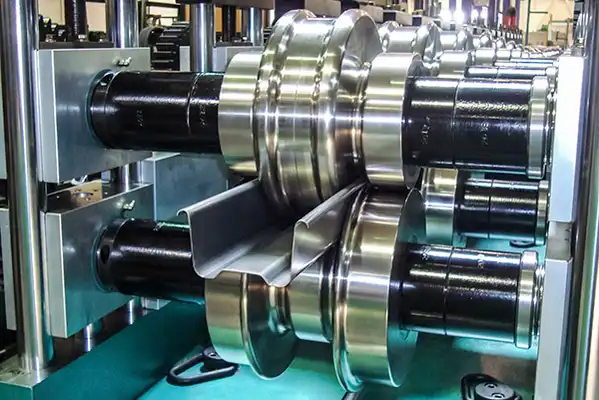

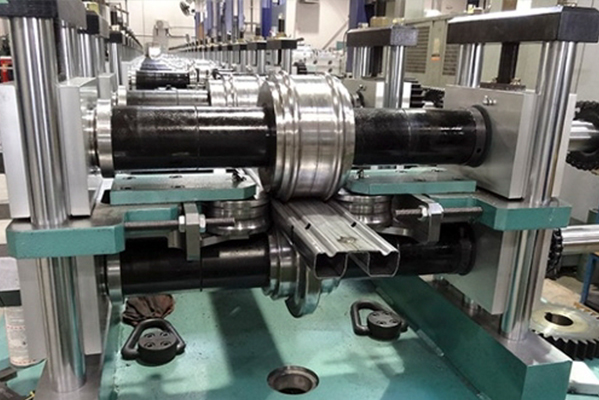

In the dynamic landscape of global manufacturing, the role of roll forming machines has become increasingly significant. These versatile machines are integral to the production of various components and structures, ranging from building materials to automotive parts. As market needs evolve, importers of roll forming machines are demonstrating remarkable adaptability, ensuring that their offerings remain aligned with the latest industry trends and customer requirements.

The evolving market needs are driven by several factors, including technological advancements, changes in consumer preferences, and the globalization of supply chains. In response, roll forming machine importers are focusing on innovation, customization, and efficiency to meet these demands. They are continuously exploring new materials, designs, and production processes that can enhance the performance and versatility of their machines.

Technological advancements play a crucial role in shaping the evolution of roll forming machines. Importers are investing in research and development to incorporate state-of-the-art features such as automation, precision control, and real-time monitoring. These innovations not only improve the accuracy and consistency of production but also reduce waste and operational costs. By staying ahead of the technology curve, importers are able to offer machines that provide a competitive edge to their customers.

Changes in consumer preferences are another significant driver of market evolution. As consumers become more discerning and demand higher quality products, roll forming machine importers are responding by offering machines that can produce intricate designs and finishes. This requires a high level of customization and flexibility, which many importers are achieving through modular designs and advanced software solutions. By enabling customers to tailor their machines to specific needs, importers are fostering a greater sense of satisfaction and loyalty.

The globalization of supply chains has also had a profound impact on the roll forming machine market. Importers are now sourcing components and materials from various countries, allowing them to access a wider range of options and reduce costs. However, this also presents challenges in terms of quality control and logistics. To address these challenges, importers are investing in robust supply chain management systems and establishing strategic partnerships with reliable suppliers.

Moreover, roll forming machine importers are increasingly focusing on after-sales support and services to differentiate themselves in the competitive market. They are offering training programs, maintenance services, and technical support to ensure that their customers can maximize the performance and lifespan of their machines. This commitment to customer satisfaction is crucial in building long-term relationships and fostering repeat business.

In conclusion, the global roll forming machine market is continuously evolving, driven by technological advancements, changes in consumer preferences, and the globalization of supply chains. Importers are demonstrating remarkable adaptability by focusing on innovation, customization, and efficiency. By staying attuned to market needs and investing in research and development, they are ensuring that their offerings remain competitive and relevant in the ever-changing manufacturing landscape. As the market continues to evolve, importers will need to remain agile and proactive to maintain their position as trusted partners in the roll forming industry.