Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 05, 2024 Visit:197 Source:ROLL FORMING MACHINES LTD

In today's manufacturing landscape, precision and efficiency are paramount. Recognizing this, a reputable supplier has announced the availability of a range of high-quality roll forming machines designed to meet the diverse needs of metalworking professionals. These machines represent a blend of advanced technology, reliability, and customization, ensuring that they can seamlessly integrate into any manufacturing process.

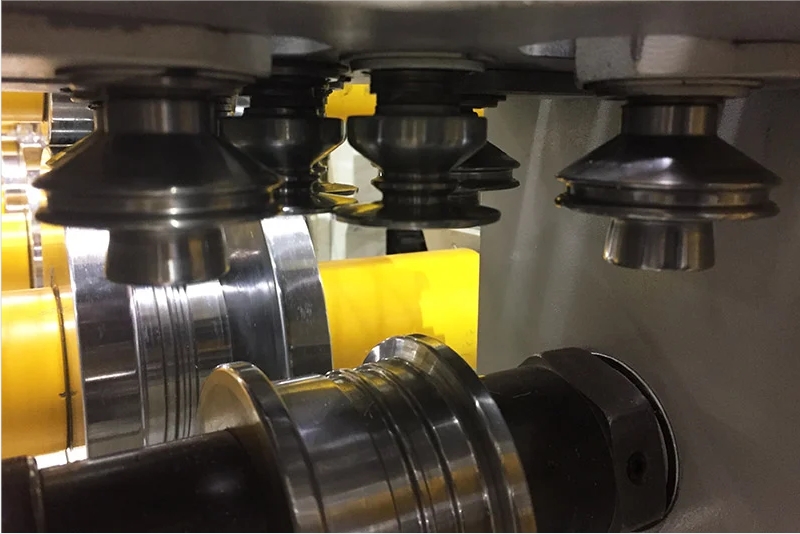

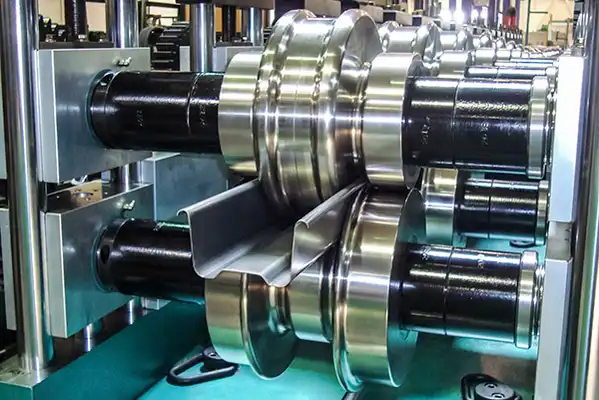

The roll forming machines on offer have been engineered to handle a wide variety of materials, from lightweight aluminum to heavy-duty steel. Their robust construction and precision engineering make them capable of forming intricate shapes and profiles with remarkable accuracy. This attention to detail ensures that finished products meet the highest standards of quality, reducing waste and enhancing overall productivity.

One of the standout features of these machines is their versatility. Whether you're producing roofing panels, automotive parts, or architectural components, there's a roll forming machine tailored to your specific requirements. The supplier offers customization options that allow clients to configure their machines to suit unique applications, ensuring that every machine is optimized for maximum performance in its intended use.

Ease of operation is another key aspect of these high-quality roll forming machines. User-friendly control systems and intuitive interfaces make it possible for operators with varying levels of experience to run the machines efficiently. This reduces the learning curve and allows manufacturers to quickly scale up production without compromising on quality.

The supplier's commitment to excellence extends beyond the product itself. Comprehensive support services, including installation, training, and maintenance, ensure that clients can maximize the benefits of their roll forming machines. Expert technicians are available to provide guidance and troubleshooting, helping clients maintain optimal machine performance and minimize downtime.

Furthermore, these roll forming machines have been designed with long-term durability in mind. High-quality materials and rigorous testing protocols ensure that they can withstand the demands of continuous use, even in the most challenging manufacturing environments. This reliability translates into lower maintenance costs and extended machine lifespan, ultimately contributing to a more sustainable business model.

The availability of these high-quality roll forming machines presents an exciting opportunity for manufacturers seeking to enhance their production capabilities. By investing in precision engineering and customization, the supplier has created a product line that not only meets current manufacturing needs but is also adaptable for future advancements.

In conclusion, the introduction of these high-quality roll forming machines marks a significant step forward in the metalworking industry. With their versatility, ease of operation, and robust construction, these machines are poised to revolutionize manufacturing processes and elevate product quality to new heights. For manufacturers looking to stay ahead of the competition, the availability of these machines represents a valuable asset in their quest for operational excellence.