Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 01, 2024 Visit:283 Source:ROLL FORMING MACHINES LTD

In the realm of metal forming, roll forming machine technology has undergone significant advancements, thanks to the relentless pursuit of innovation by leading suppliers in the industry. These suppliers have consistently pushed the boundaries of what is possible, developing new technologies and features that enhance the efficiency, precision, and versatility of roll forming machines.

One of the most notable innovations in roll forming machine technology is the integration of advanced automation systems. Leading suppliers have incorporated robotics, sensors, and other automation components into their machines, enabling them to perform complex forming tasks with unprecedented accuracy and consistency. This automation not only reduces the need for manual labor, but also minimizes the risk of human error, leading to higher quality outputs.

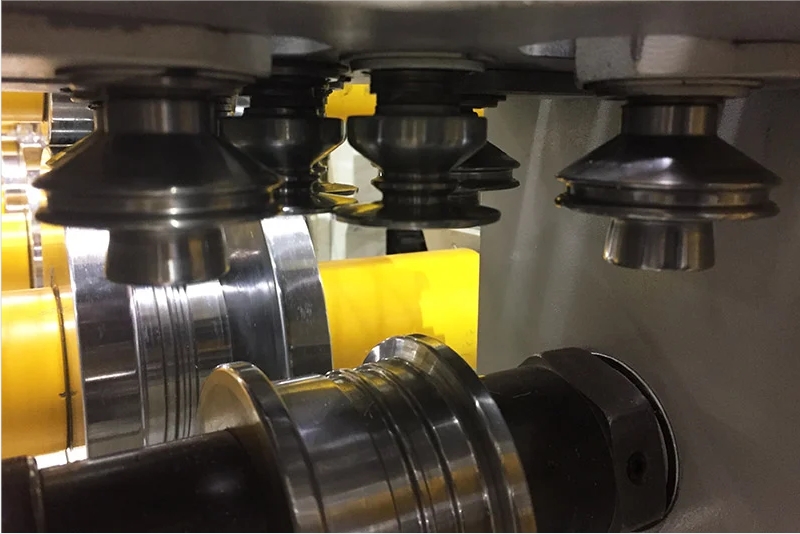

Another significant innovation is the development of more sophisticated control systems. Modern roll forming machines are equipped with advanced control systems that utilize state-of-the-art algorithms software to optimize the forming process. These systems can monitor and adjust the machine's operations in and real-time, ensuring that the final product meets the exact specifications required by the customer. This level of precision is crucial in industries where tight tolerances high standards of quality are the norm.

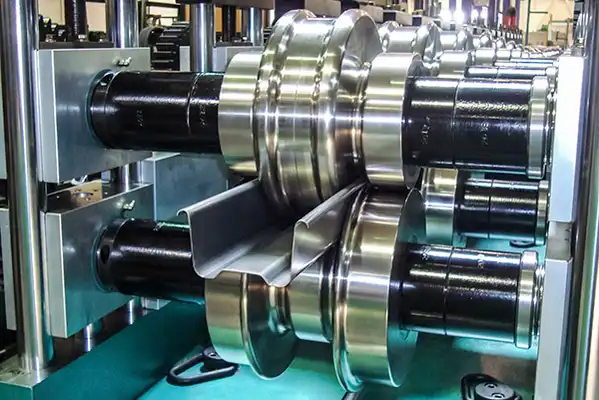

Leading suppliers have also focused on improving the flexibility and versatility of roll forming machines. Traditional roll forming machines were often limited to producing a specific range of shapes and sizes. However, with the advent of modular and adjustable roll tooling, suppliers are now able to offer machines that can be easily configured to produce a wide variety of different profiles. This adaptability allows manufacturers to quickly switch between different products, reducing setup times and increasing overall productivity.

In addition to these innovations, leading suppliers have also invested in the development of new materials and manufacturing processes. Advances in materials science have led to the creation of stronger, lighter, and more durable metals that can be formed into complex shapes using roll forming machines. These new materials are ideal for applications in industries such as aerospace and automotive, where weight reduction and improved performance are critical.

Furthermore, suppliers have also implemented new manufacturing processes that are more efficient and cost-effective. Techniques such as precision machining and additive manufacturing have been integrated into the production of roll forming machines, enabling suppliers to create components with tighter tolerances and reduced waste. These processes also allow for faster turnaround times, enabling suppliers to quickly respond to customer demands.

As the industry continues to evolve, leading suppliers remain committed to driving innovation in roll forming machine technology. They are constantly exploring new ways to improve the efficiency, precision, and versatility of their machines, ensuring that they remain at the forefront of the metal forming industry.

In conclusion, the innovations in roll forming machine technology from leading suppliers have had a profound impact on the metal forming industry. By integrating advanced automation systems, sophisticated control systems, modular roll tooling, and new materials and manufacturing processes, suppliers have transformed roll forming machines into powerful, flexible, and efficient tools that meet the diverse needs of manufacturers across various industries.