Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 13, 2024 Visit:288 Source:ROLL FORMING MACHINES LTD

In the vast landscape of manufacturing processes, roll forming machines have emerged as indispensable tools, known for their remarkable precision and versatility. These machines are designed to shape and form metals into various desired shapes and sections through a continuous bending process. Their wide range of applications across diverse industries underscores their importance and the benefits they bring to production processes.

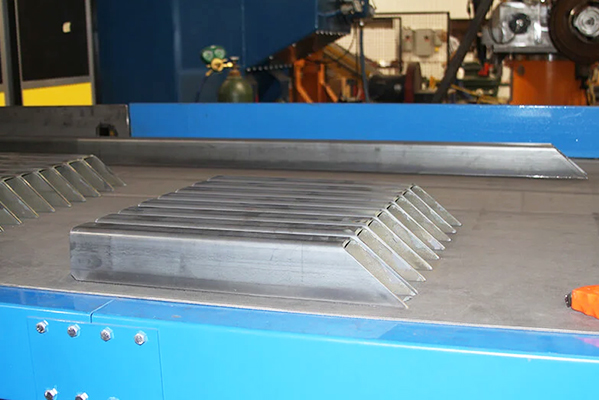

Roll forming machines achieve precision through a series of carefully engineered forming rolls. These rolls are meticulously arranged and spaced to gradually bend the metal strip into the final desired shape. The process begins with a flat metal strip being fed into the machine, which then passes through a series of rolls, each progressively altering the strip's contour until the final shape is achieved. This gradual deformation ensures that the metal retains its structural integrity and achieves a high degree of accuracy in its final form.

One of the key advantages of roll forming machines lies in their versatility. These machines can be configured to produce a multitude of shapes and sizes, from simple channels and angles to complex custom profiles. This flexibility allows manufacturers to adapt quickly to changing market demands and produce a wide variety of products without the need for extensive tooling changes or reconfigurations. The ability to switch between different profiles with minimal downtime enhances productivity and reduces costs, making roll forming an economically viable option for many applications.

In the automotive industry, roll forming machines are used to produce structural components such as door frames, roof rails, and bumper beams. The precision and consistency of the roll forming process ensure that these components meet strict safety and performance standards. Similarly, in the construction sector, roll formed steel is used in the production of building elements like roofing, siding, and structural framing. Its strength, durability, and cost-effectiveness make it a preferred material for many construction projects.

Roll forming machines also find application in the production of furniture components, household appliances, and aerospace parts. The ability to create intricate shapes and maintain tight tolerances makes roll forming an ideal choice for these industries, where precision and reliability are paramount. Furthermore, the continuous nature of the roll forming process allows for high-volume production, making it well-suited for mass manufacturing environments.

Advancements in technology have further enhanced the capabilities of roll forming machines. Modern machines are equipped with advanced control systems and sensors that monitor and adjust the forming process in real-time. This ensures that the final product meets strict quality standards and maintains consistent quality throughout production runs. Additionally, the integration of automation and robotics has improved the efficiency and safety of roll forming operations, reducing manual labor and minimizing the risk of errors.

In conclusion, roll forming machines have established themselves as indispensable tools in the manufacturing world, thanks to their precision and versatility. Their ability to produce a wide range of shapes and sizes with high accuracy and consistency makes them ideal for numerous applications across diverse industries. As technology continues to evolve, roll forming machines will likely become even more efficient and capable, further cementing their role in the future of manufacturing.