Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:260 Source:ROLL FORMING MACHINES LTD

In the ever-evolving landscape of manufacturing, roll forming machine manufacturers have emerged as key players committed to pushing the boundaries of precision and efficiency. These manufacturers are not only meeting but exceeding the expectations of their clients by delivering machines that offer unparalleled accuracy in shaping materials and optimized production processes.

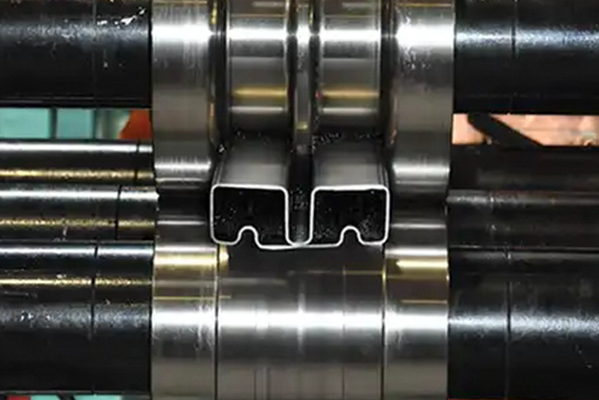

is a cornerstone of roll forming technology. Roll forming machines are designed to shape flat metal sheets into three-dimensional profiles with remarkable accuracy. Manufacturers have invested heavily in research and development to refine the processes and technologies that underpin roll forming. Advanced computer-aided design (CAD) software and precision machining techniques enable manufacturers to create rolls that produce parts with tight tolerances and consistent quality. This focus on precision is crucial in industries such as automotive, aerospace, and construction, where even the smallest deviations can compromise the performance and safety of the final product.

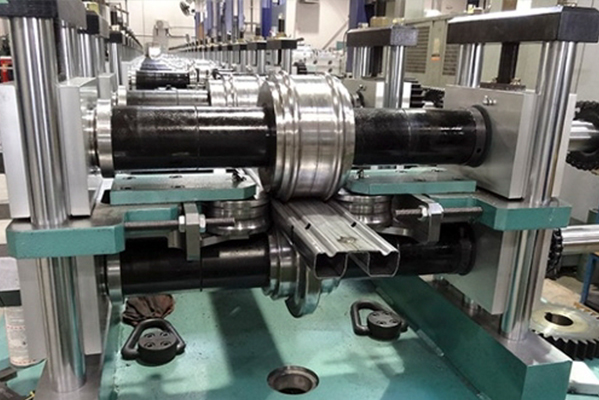

Efficiency is another area where roll forming machine manufacturers are making significant strides. The traditional methods of shaping metal, such as bending or welding, are often labor-intensive and time-consuming. Roll forming, however, is a continuous process that can significantly reduce production time and labor costs. Manufacturers are constantly innovating to enhance the efficiency of their machines, incorporating features such as automated feed systems, high-speed rolling capabilities, and advanced control systems. These advancements not only increase throughput but also minimize material waste and energy consumption, making roll forming an economically viable option for a wide range of applications.

The focus on precision and efficiency is also reflected in the customization options offered by roll forming machine manufacturers. Clients can specify the exact dimensions, materials, and tolerances required for their applications, and manufacturers can tailor their machines to meet these requirements. This level of customization ensures that roll forming machines are not only versatile but also highly effective in producing parts that meet the specific needs of each industry.

Moreover, the rise of Industry 4.0 and the Internet of Things (IoT) is further transforming the roll forming machine industry. Manufacturers are integrating smart sensors, data analytics, and machine learning algorithms into their machines to improve monitoring, control, and optimization. This digital transformation enables manufacturers to achieve even higher levels of precision and efficiency, while also providing valuable insights into machine performance and maintenance needs.

In conclusion, roll forming machine manufacturers are at the forefront of the manufacturing industry's drive for precision and efficiency. By continuously innovating and refining their technologies, these manufacturers are delivering machines that meet the evolving needs of clients across various industries. The focus on precision ensures that parts are produced with consistent quality and tight tolerances, while the emphasis on efficiency drives down costs and improves production times. As the manufacturing landscape continues to evolve, roll forming machine manufacturers will remain key players in driving innovation and progress.