Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:258 Source:ROLL FORMING MACHINES LTD

In the ever-evolving landscape of manufacturing, roll forming machines have emerged as pivotal tools driving efficiency, precision, and versatility. These machines, which bend and shape flat metal sheets into desired cross-sectional profiles through a series of consecutive rolls, are now undergoing significant innovations that promise to reshape the future of industrial production.

Advancements in Technology and Design

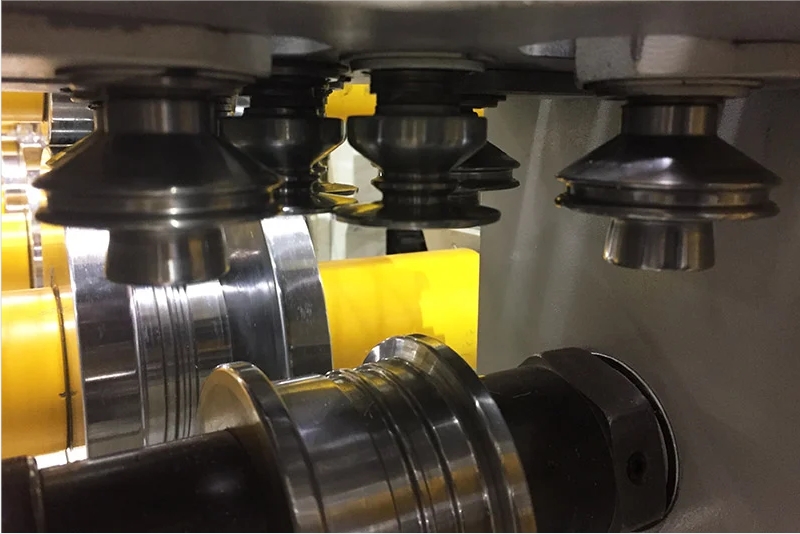

One of the most notable innovations in roll forming machines lies in the advancements in technology and design. Modern roll forming machines are equipped with advanced sensors and control systems that enable real-time monitoring and adjustment of the forming process. This ensures higher accuracy and consistency in product output, reducing waste and enhancing overall productivity.

Moreover, the design of roll forming machines has become more modular and flexible, allowing manufacturers to quickly switch between different forming operations without extensive setup times. This adaptability is crucial in today's fast-paced manufacturing environment, where the ability to respond swiftly to market demands and customer preferences is a competitive advantage.

Increased Automation and Integration

Automation is another key trend shaping the future of roll forming machines. With the integration of robotics, artificial intelligence (AI), and machine learning, roll forming processes are becoming increasingly automated. Automated roll forming lines can operate with minimal human intervention, reducing labor costs and minimizing the risk of human error.

Furthermore, the integration of roll forming machines with other manufacturing processes, such as welding, cutting, and surface treatment, is becoming more seamless. This level of integration fosters a more streamlined production workflow, enhancing overall efficiency and reducing lead times.

Material Handling and Process Optimization

Innovations in material handling and process optimization are also playing a significant role in the evolution of roll forming machines. Advanced feeding and conveying systems ensure that metal sheets are delivered to the roll forming machine with the necessary precision and speed. This, in turn, contributes to higher throughput and better utilization of machine capacity.

In addition, process optimization techniques, such as predictive maintenance and energy management, are being increasingly adopted in roll forming operations. Predictive maintenance, for instance, uses data analytics to identify potential machine failures before they occur, enabling manufacturers to schedule maintenance activities and minimize downtime. Energy management systems, on the other hand, help reduce energy consumption and operational costs, making roll forming processes more sustainable in the long run.

Customized Solutions for Diverse Applications

As manufacturing needs become more diverse and specialized, roll forming machines are evolving to provide customized solutions for a wide range of applications. From automotive components and building materials to consumer products and aerospace parts, roll forming machines can now be tailored to meet the unique requirements of various industries.

This customization extends to the ability to produce complex shapes and profiles with tight tolerances. Advanced roll forming technologies, such as multi-axis roll forming and variable-geometry rolls, enable manufacturers to create intricate designs that were previously impossible or impractical to produce.

Conclusion

In conclusion, roll forming machine innovations are shaping the future of manufacturing in significant ways. From advancements in technology and design to increased automation and integration, material handling and process optimization, and customized solutions for diverse applications, these innovations are driving efficiency, precision, and versatility in industrial production. As manufacturers continue to embrace these innovations, they will be better positioned to meet the challenges and opportunities of the evolving manufacturing landscape.