Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:242 Source:ROLL FORMING MACHINES LTD

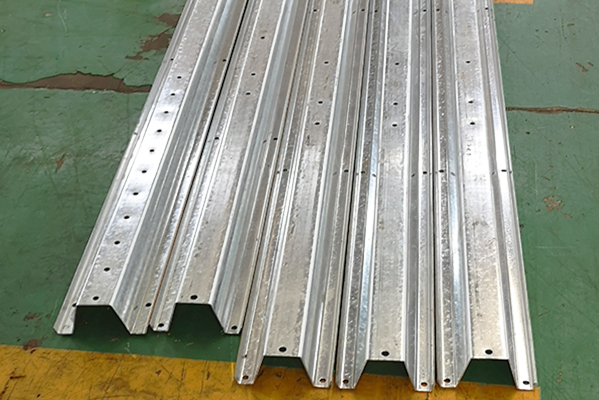

In the dynamic landscape of manufacturing, roll forming machines have emerged as versatile tools with widespread applications across numerous industries. These machines, which utilize a series of rollers to shape metal sheets into desired profiles, have seen their use expand significantly in recent years, driven by technological advancements and the increasing demand for precision and efficiency in production processes.

One of the sectors where roll forming machines have made a significant impact is the automotive industry. The need for lightweight yet strong components has led to the widespread adoption of roll forming technology for producing car frames, door beams, and other structural parts. By utilizing high-strength materials like aluminum and advanced high-strength steel (AHSS), roll forming machines can create intricate shapes with consistent wall thicknesses, optimizing vehicle performance and fuel efficiency.

The construction industry is another key sector benefiting from roll forming machine applications. From roof trusses and wall panels to steel beams and structural framing, roll forming machines enable manufacturers to produce a wide range of building components with high precision and speed. This technology not only enhances the structural integrity of buildings but also facilitates faster and more efficient construction processes, contributing to cost savings and shorter project timelines.

In the aerospace industry, roll forming machines play a crucial role in the production of aircraft components. The demand for lightweight, strong, and corrosion-resistant materials has led to the use of titanium, aluminum alloys, and composite materials in aircraft structures. Roll forming machines can accurately shape these materials into complex geometries, ensuring that aircraft components meet stringent safety and performance standards.

The furniture industry has also seen an increase in the use of roll forming machines. From office partitions and shelving units to bed frames and kitchen cabinets, roll forming technology allows manufacturers to produce high-quality, durable, and cost-effective furniture components. The precision and repeatability of roll forming machines ensure that furniture pieces are consistent in size and shape, enhancing overall product quality and customer satisfaction.

The electrical and electronics sector has also benefited from the versatility of roll forming machines. Components such as switchboards, enclosures, and racks are often produced using roll forming technology. The ability to create intricate shapes and precise holes with minimal waste makes roll forming an ideal choice for these applications, supporting the production of reliable and aesthetically pleasing electrical and electronic devices.

Beyond these sectors, roll forming machines have found applications in various other industries, including agricultural equipment, HVAC systems, and transportation infrastructure. The versatility of roll forming technology allows manufacturers to adapt to the unique requirements of each industry, producing components that meet specific performance and aesthetic criteria.

In conclusion, the applications of roll forming machines have expanded significantly across multiple sectors, driven by the need for precision, efficiency, and cost-effectiveness in manufacturing processes. From automotive components to construction materials and aerospace structures, roll forming technology has become an indispensable tool in the production of a wide range of products. As technological advancements continue to drive the evolution of roll forming machines, their applications are likely to expand further, supporting the growth and innovation of numerous industries.