Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 07, 2024 Visit:243 Source:ROLL FORMING MACHINES LTD

In the dynamic world of metalworking, manufacturers are constantly seeking equipment that can meet their diverse needs with precision and efficiency. Recognizing this, a reputable supplier has recently expanded its offerings with a wide range of roll forming machines now on sale. These machines cater to various industries and applications, providing manufacturers with the flexibility and capability to produce a wide array of metal products.

The roll forming machines available for sale come in various sizes and configurations, ensuring that there is a perfect fit for every manufacturing requirement. From small, benchtop models suitable for prototype development to large, industrial-scale machines capable of handling heavy-duty production runs, the range covers a broad spectrum of needs. This variety allows manufacturers to choose the machine that best aligns with their production volume, workspace, and budget constraints.

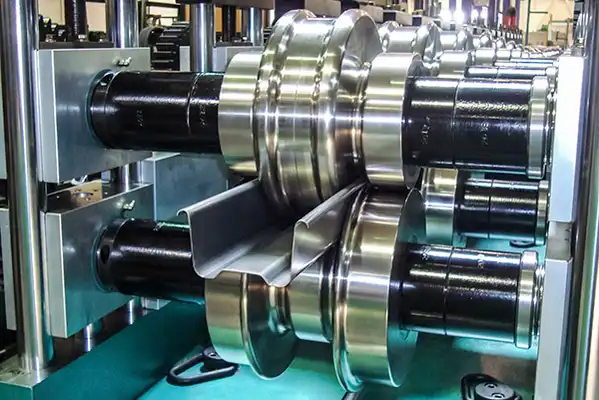

One of the standout features of this wide range of roll forming machines is their versatility. With interchangeable tooling and adjustable roller sets, these machines can be configured to form a multitude of shapes and profiles. Whether you need to produce straight channels, curved pipes, or intricate architectural elements, there is a machine in this range that can meet your specifications. This adaptability ensures that manufacturers can stay agile and respond quickly to market demands, producing a variety of products without the need for multiple pieces of equipment.

Precision is another key aspect of these roll forming machines. Advanced manufacturing techniques and high-quality materials ensure that each machine delivers consistent and accurate results. The rollers are precision-ground to ensure smooth and even metal deformation, minimizing waste and enhancing product quality. This attention to detail is crucial for industries where precision is paramount, such as aerospace, automotive, and electronics.

Efficiency is also a hallmark of this range of roll forming machines. Many models are equipped with automation features that streamline production processes, reducing labor costs and increasing throughput. Automated feeding, positioning, and cutting mechanisms minimize downtime and ensure that operations run smoothly. Additionally, some machines offer real-time monitoring and diagnostics, allowing operators to quickly identify and resolve any issues that arise, further enhancing productivity.

Customer support is another area where this supplier excels. Technical experts are available to provide guidance on machine selection, setup, and optimization. Training programs and after-sales support ensure that manufacturers can maximize the potential of their new roll forming machines, achieving optimal performance and productivity.

In conclusion, the wide range of roll forming machines now on sale offers manufacturers a versatile and efficient solution for their metalworking needs. With options to suit every size and type of production, these machines provide the precision, adaptability, and efficiency required to stay competitive in today's fast-paced manufacturing environment. Whether you're a small startup or a large-scale producer, investing in one of these machines is a strategic decision that can significantly enhance your manufacturing capabilities.