Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 11, 2024 Visit:296 Source:ROLL FORMING MACHINES LTD

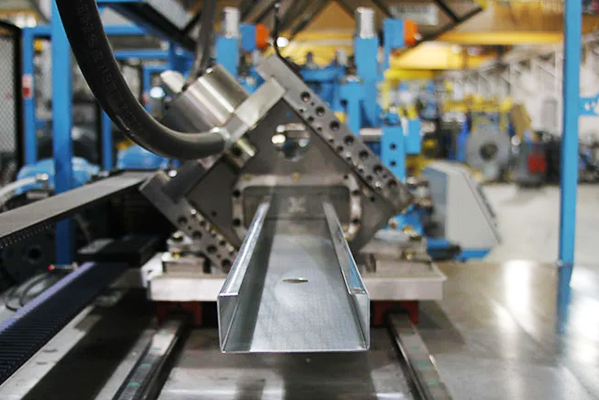

In the dynamic world of metal fabrication, roll forming machine technology has emerged as a cornerstone of modern manufacturing. Recent innovations in this field have significantly enhanced production quality, pushing the boundaries of what is possible in terms of precision, efficiency, and versatility. By embracing these advancements, manufacturers can achieve unprecedented levels of product excellence, meeting and even exceeding the expectations of their customers.

One of the most significant innovations in roll forming machine technology is the integration of advanced control systems. These systems utilize sophisticated algorithms and sensors to monitor and optimize the forming process in real-time. By precisely controlling the speed, temperature, and pressure applied by the rollers, manufacturers can ensure consistent quality throughout the production run. This level of precision not only minimizes defects but also enhances the overall structural integrity of the finished products.

Another innovation that has boosted production quality is the development of modular tooling systems for roll forming machines. These systems enable manufacturers to quickly and easily switch between different roller sets, allowing for the production of a wide variety of shapes and profiles. This versatility not only increases flexibility but also reduces changeover times, enhancing overall productivity. Moreover, modular tooling systems can be customized to meet specific customer requirements, ensuring that the final product meets exact specifications.

In terms of material handling, roll forming machine technology has also seen significant improvements. Advanced feeding mechanisms, such as servo-driven conveyors and magnetic separators, ensure that the metal sheet is fed into the machine smoothly and consistently. This minimizes the risk of wrinkles, tears, and other defects that can compromise the quality of the finished product. Additionally, high-speed roller sets have been developed to keep pace with modern production demands, further enhancing throughput and efficiency.

The integration of automation and robotics has also played a pivotal role in boosting production quality in roll forming. Automated systems can perform tasks such as cutting, bending, and welding with unprecedented precision and consistency. By automating these processes, manufacturers can reduce human error and minimize variation in product quality. Furthermore, robotics enables manufacturers to handle heavy materials safely and efficiently, reducing the risk of accidents and injuries in the workplace.

In addition to these technological advancements, roll forming machine manufacturers have also focused on improving the ergonomics and user-friendliness of their machines. Modern roll forming machines are designed with intuitive control panels and easy-to-use interfaces, making it easier for operators to monitor and adjust the forming process. This enhances operator satisfaction and productivity, ultimately contributing to improved production quality.

Another notable innovation in roll forming machine technology is the development of in-process inspection systems. These systems utilize advanced sensors and imaging technology to monitor the forming process in real-time, detecting and correcting defects before they become critical. By identifying and addressing issues early in the production cycle, manufacturers can minimize waste and ensure that only high-quality products are shipped to customers.

Moreover, the integration of Internet of Things (IoT) technology has enabled manufacturers to collect and analyze data from their roll forming machines in real-time. This data can be used to identify trends, predict maintenance needs, and optimize production processes. By leveraging IoT technology, manufacturers can achieve greater transparency and control over their production operations, further enhancing production quality.

In conclusion, innovations in roll forming machine technology have had a profound impact on production quality in the metal fabrication industry. By embracing these advancements, manufacturers can achieve unprecedented levels of precision, efficiency, and versatility, meeting and exceeding the expectations of their customers. As the industry continues to evolve, it is likely that even more innovations will emerge, driving further improvements in production quality and competitiveness.