Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 10, 2024 Visit:303 Source:ROLL FORMING MACHINES LTD

In the realm of metal fabrication, the roll forming machine process has emerged as a cornerstone of modern manufacturing. This sophisticated technique combines precision, versatility, and efficiency to produce a wide array of metal products with unparalleled quality. By leveraging the roll forming process, manufacturers can significantly enhance their production capabilities, reduce costs, and maintain a competitive edge in the market.

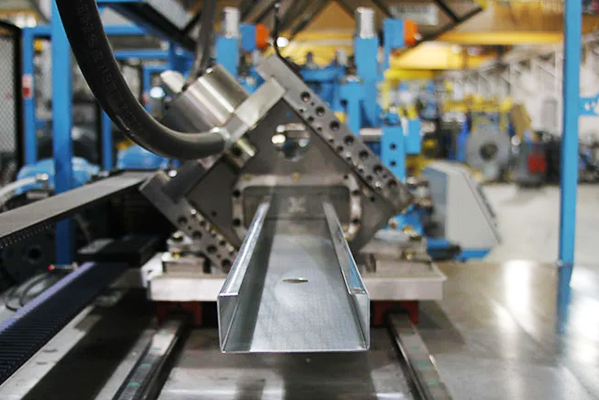

The roll forming machine process begins with a flat sheet of metal, which is fed into the machine. As the sheet passes through a series of precisely engineered rollers, it is gradually shaped into the desired profile. Each roller set applies incremental deformation to the metal, ensuring a smooth and consistent transition from flat to formed. This gradual forming process minimizes stress and distortion, resulting in high-quality finished products.

One of the key advantages of roll forming is its precision. The rollers are meticulously designed and manufactured to maintain tight tolerances throughout the forming process. This ensures that the final product meets exact specifications, reducing waste and enhancing overall quality. Precision is particularly critical in industries where dimensional accuracy is paramount, such as aerospace, automotive, and electronics.

In addition to precision, roll forming offers exceptional versatility. The process can be adapted to produce a vast array of shapes and profiles, from simple channels and angles to complex architectural elements and custom parts. This versatility allows manufacturers to quickly switch between different products, reducing changeover times and optimizing production capacity. Furthermore, roll forming machines can be equipped with modular tooling systems that enable easy configuration and reconfiguration, further enhancing flexibility.

Efficiency is another significant benefit of the roll forming machine process. High-speed roller sets and automated feeding mechanisms minimize downtime and maximize throughput. Advanced control systems monitor and optimize the forming process in real-time, ensuring consistent quality and reducing the need for manual intervention. This level of automation not only increases production speed but also reduces labor costs, enhancing overall profitability.

The roll forming process also contributes to cost savings by minimizing material waste. The incremental deformation applied by the rollers ensures that the metal is used efficiently, with minimal scrap generated. Additionally, roll forming machines can be equipped with cut-to-length capabilities, enabling manufacturers to produce custom-sized parts with minimal material loss. These cost savings can be particularly significant in high-volume production environments.

Another notable advantage of roll forming is its scalability. Manufacturers can invest in machines with varying capacities to suit their production needs. As demand grows, they can easily upgrade to larger, more efficient machines without compromising the quality of their products. This scalability ensures that roll forming remains a viable option for businesses of all sizes, from small startups to large-scale enterprises.

In addition to these tangible benefits, the roll forming machine process also offers intangible advantages. It promotes a culture of innovation and continuous improvement, encouraging manufacturers to explore new product designs and manufacturing techniques. The precision and versatility of roll forming machines enable manufacturers to experiment with complex shapes and materials, driving innovation and fostering a competitive edge.

In conclusion, the roll forming machine process is a powerful tool for enhancing metal fabrication efficiency. By leveraging this sophisticated technique, manufacturers can achieve precision, versatility, efficiency, and cost savings, all while maintaining a competitive edge in the market. As the metal fabrication industry continues to evolve, roll forming will undoubtedly play a pivotal role in shaping the future of manufacturing.