Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:247 Source:ROLL FORMING MACHINES LTD

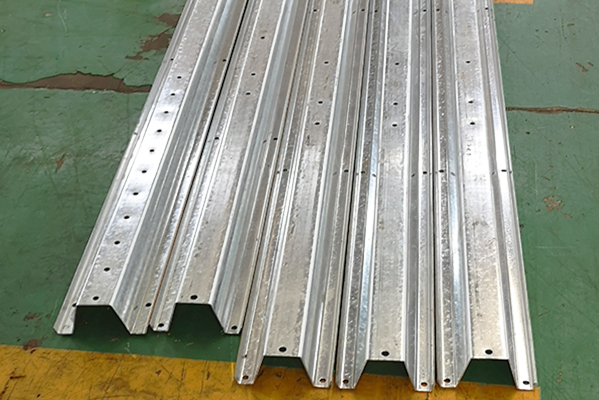

In the evolving landscape of manufacturing, advancements in technology continue to reshape the industry. Among the latest innovations, the latest models of roll forming machines have emerged as essential tools for metal shaping and fabrication. These state-of-the-art machines offer unparalleled precision, efficiency, and versatility, making them ideal for a wide range of applications across various industries.

The latest roll forming machines have been designed with enhanced automation capabilities. This allows for seamless integration into existing production lines, ensuring that metal sheets can be processed with minimal human intervention. Automation not only boosts productivity but also reduces the risk of human error, leading to higher quality output.

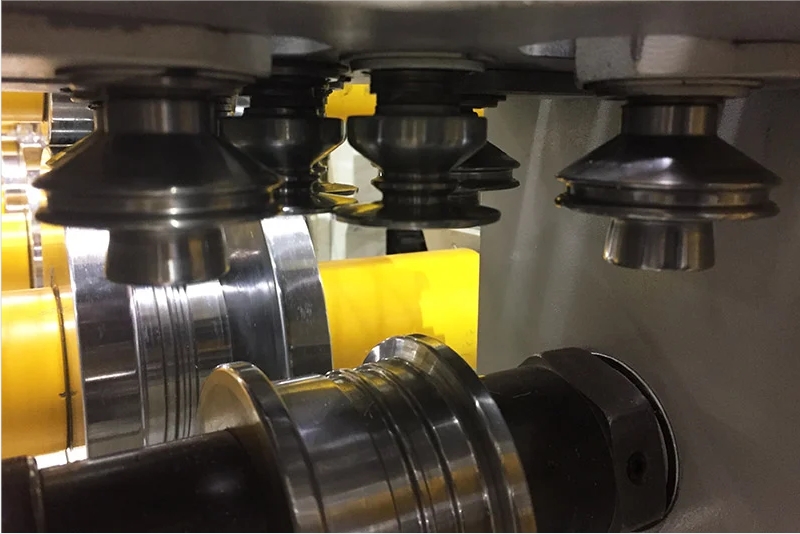

One of the key features of these new models is their advanced control systems. Equipped with cutting-edge software, these systems enable operators to program the machines with intricate shapes and specifications. The software can also monitor and adjust the forming process in real-time, ensuring that the final product meets exacting standards.

Another significant improvement in the latest roll forming machines is their ability to handle a wider range of materials. From lightweight aluminum to heavy-duty steel, these machines can shape a variety of metals with precision and ease. This versatility makes them suitable for applications in diverse industries, such as automotive, aerospace, construction, and furniture manufacturing.

Efficiency is another hallmark of the latest roll forming machines. Thanks to advanced mechanical designs and energy-efficient motors, these machines can operate continuously at high speeds without compromising accuracy. This ensures that businesses can maximize their production capacity while minimizing downtime and maintenance requirements.

Moreover, the latest models of roll forming machines come with robust safety features. Safety guards, emergency stop buttons, and sensors are just a few of the protective measures incorporated into these machines. These features help to create a safer work environment, reducing the risk of accidents and injuries.

The manufacturers of these latest roll forming machines have also focused on ease of use. Intuitive control panels and user-friendly interfaces make it easier for operators to program and monitor the machines. Additionally, comprehensive documentation and training resources are provided to ensure that operators can maximize the machines' potential.

The design of these machines has also evolved to cater to the aesthetic demands of modern manufacturing. Sleek, ergonomic designs not only enhance the visual appeal of the machines but also improve operator comfort and ergonomics. This contributes to a more pleasant work environment and can increase operator productivity.

In terms of customization, the latest roll forming machines offer numerous options. Manufacturers can tailor the machines to meet specific production requirements, including custom roll sets, adjustable forming stations, and specialized tooling. This flexibility allows businesses to optimize their manufacturing processes for maximum efficiency and productivity.

In conclusion, the latest models of roll forming machines represent a significant leap forward in manufacturing technology. With enhanced automation, advanced control systems, versatility in material handling, high efficiency, robust safety features, ease of use, and aesthetic appeal, these machines are poised to revolutionize the metal shaping and fabrication industry. For businesses looking to stay ahead of the competition, investing in these latest roll forming machines is a strategic decision that can yield significant benefits.