Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:248 Source:ROLL FORMING MACHINES LTD

In the competitive world of manufacturing, precision and durability are paramount to producing high-quality products efficiently. Roll forming machines, which are now widely available for sale, have emerged as indispensable tools that excel in both areas. These machines have been engineered to meet the evolving needs of modern manufacturing, offering unmatched accuracy and longevity that set them apart from traditional forming methods.

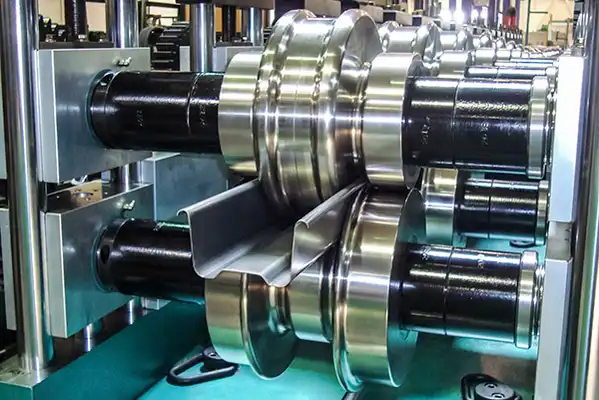

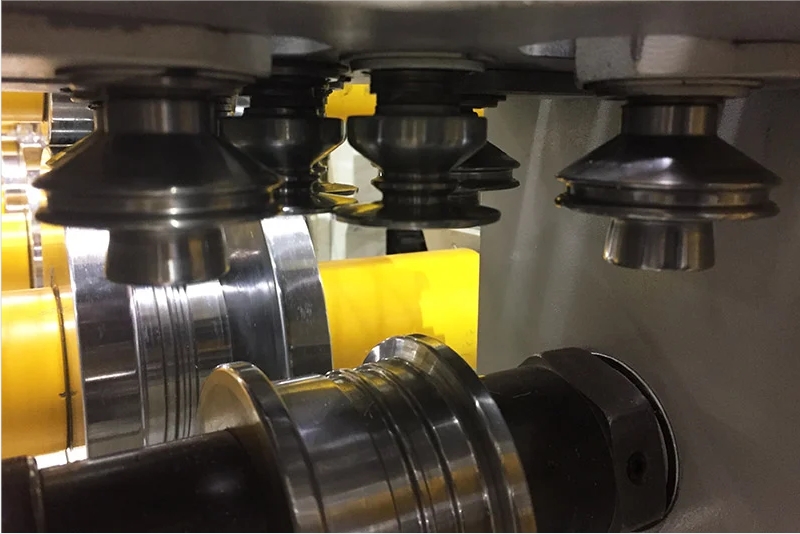

Precision is a defining characteristic of roll forming machines. By utilizing a series of precision-engineered rolls, these machines can shape metal sheets into intricate profiles with remarkable accuracy. The rolls are carefully designed and machined to ensure that each pass through the machine results in a perfectly formed product. This level of precision is crucial in industries such as automotive, aerospace, and electronics, where even the smallest deviations can compromise the performance and safety of the final product.

Moreover, roll forming machines are renowned for their durability. Constructed from high-quality materials and built to withstand the rigors of continuous operation, these machines are designed to last for many years. The robust design and precision engineering of the rolls ensure that they maintain their shape and performance over time, minimizing the need for maintenance and repairs. This durability not only reduces operational costs but also minimizes downtime, allowing manufacturers to maintain consistent production schedules.

The precision and durability of roll forming machines are enhanced by their advanced control systems. Modern machines are equipped with sophisticated electronics and software that enable operators to monitor and adjust the forming process in real-time. This ensures that even the most complex profiles can be produced with consistent accuracy and repeatability. Additionally, the control systems can be programmed to optimize the forming process for different materials and thicknesses, further enhancing the machines' versatility and flexibility.

Another advantage of roll forming machines is their ability to handle a wide range of materials. From lightweight aluminum and stainless steel to heavier gauge metals, these machines can shape a variety of materials with precision and ease. This versatility makes them suitable for a wide range of manufacturing applications, from automotive components and aerospace parts to building products and consumer goods.

In addition to precision and durability, roll forming machines offer numerous other benefits that make them attractive to manufacturers. They are highly efficient, capable of producing large quantities of formed parts quickly and consistently. They also require minimal operator intervention, reducing labor costs and increasing productivity. Furthermore, the continuous forming process minimizes material waste, contributing to cost savings and improved sustainability.

When considering the purchase of roll forming machines, it is essential to select a reputable manufacturer with a proven track record of delivering high-quality products. Look for manufacturers that offer a wide range of machine sizes and configurations to suit different production needs. They should also provide comprehensive technical support and after-sales service to ensure that the machines continue to operate efficiently and effectively over time.

In conclusion, roll forming machines offer a combination of precision and durability that is unmatched by traditional forming methods. Their ability to produce high-quality parts consistently and efficiently makes them an invaluable asset to manufacturers across a wide range of industries. With the right machine and support from a reputable manufacturer, businesses can leverage the precision and durability of roll forming machines to stay ahead of the competition and meet the ever-evolving demands of modern manufacturing.