Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:255 Source:ROLL FORMING MACHINES LTD

In the realm of manufacturing, efficiency is a cornerstone of success. It not only drives down costs but also ensures timely delivery of high-quality products. One process that significantly boosts manufacturing efficiency is roll forming, a method that utilizes roll forming machines to shape metal sheets into various profiles. This article explores how the roll forming machine process improves manufacturing efficiency, highlighting its key advantages and the ways it contributes to streamlined production.

Continuous Production for Higher Output

One of the most notable advantages of roll forming is its continuous production capability. Unlike other forming methods that require stopping and starting, roll forming machines operate continuously, shaping metal sheets as they pass through a series of precision-engineered rolls. This continuous process allows manufacturers to produce large quantities of formed parts in a short period, significantly increasing output and reducing production time.

Enhanced Precision for Quality Assurance

Precision is crucial in manufacturing, especially when dealing with complex parts that require intricate shaping. Roll forming machines excel in this area, thanks to their advanced design and engineering. The rolls are precisely machined to ensure that each pass through the machine results in a perfectly formed product. This high level of precision minimizes waste and rework, ensuring that manufacturers can produce parts that meet or exceed quality standards consistently.

Material Efficiency for Cost Savings

Material waste is a significant concern in manufacturing, often leading to increased costs and reduced profitability. Roll forming machines are designed to minimize material waste, as the continuous forming process ensures that every piece of metal is utilized efficiently. Additionally, the machines can be programmed to optimize the forming process for different materials and thicknesses, further reducing waste and maximizing material usage.

Reduced Labor Costs with Automation

Labor costs are a significant expense in manufacturing, particularly when producing large quantities of parts. Roll forming machines are highly automated, requiring minimal operator intervention. This automation not only reduces labor costs but also ensures consistent quality and repeatability in the forming process. Operators can monitor the machines from a control panel, making adjustments as needed to maintain precision and efficiency.

Versatility for Diverse Applications

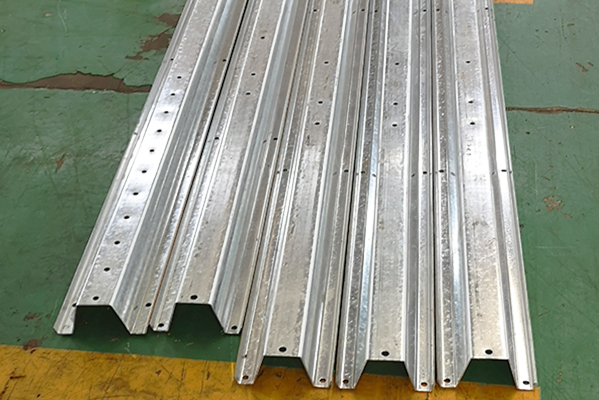

Roll forming machines are versatile tools that can be used to produce a wide range of parts for various industries. From automotive components and aerospace parts to building products and consumer goods, the versatility of roll forming machines makes them an essential asset in many manufacturing settings. This versatility allows manufacturers to produce a diverse range of products without needing multiple forming machines, further enhancing efficiency and reducing costs.

Scalability for Growth

As manufacturing businesses grow, they often need to scale their production capabilities to meet increased demand. Roll forming machines are scalable, allowing manufacturers to add additional rolls or upgrade to larger machines as needed. This scalability ensures that manufacturers can maintain efficient production levels as they expand their operations, without the need for significant capital investments in new equipment.

Conclusion

The roll forming machine process is a powerful tool for enhancing manufacturing efficiency. Its continuous production capability, precision, material efficiency, automation, versatility, and scalability make it an invaluable asset to manufacturers across a wide range of industries. By leveraging the advantages of roll forming, businesses can improve their production processes, reduce costs, and increase profitability. As manufacturing continues to evolve, the role of roll forming machines in enhancing efficiency will become even more critical, driving innovation and growth in the industry.